AUTOMATION

Let’s AUTOMATE & Produce Quality For the Better Tomorrow.

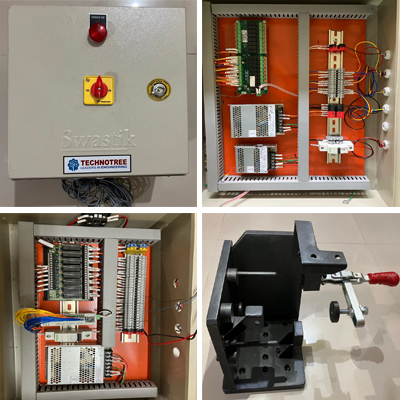

We are renowned System integrator and Industrial Automation buddy. Experience in the Development of Challenging projects to amaze our Customers. We are majorly focused on System Integration, Special purpose machines, Automatic Poka Yoke using PLC and SCADA systems.

SUCCESSFULLY EXECUITED PROJECTS-

aUTOMATIC PACKAGING POKA YOKE

This project is designed using LABVIEW and PLC Automation for the mistake proof packaging.

- Product received and Scanned at Scanner Input

- Confirmed type of product and Signal sent to particular bin and lamp indication glows at packaging station.

- If product placed at assigned bin then lamp goes off and scanning allows for next part. Closed loop system.

- If product placed at wrong bin, alarm and red light indication at Station. And scanning stops.

- If product placed into correct location/bin. Scanning start again.

- Scanning continuous until box gets full.

- Once box is full. Then scanning start again and shows indication on screen as well as at station.

- Prints label automatically. Remove full box manually and load empty box at station then scanning resumes.

- Process continue till STOP.

FLATNESS CHECKING MACHINE

This System is designed for the checking of flatness and distance of collar of casting part from the zero line using LVDT sensors.

- Casting part is placed on the zero line set plate for checking flatness.

- LVDT sensors are placed in the system so that they will check the distance of flat area with respect to zero surface.

- If flat surface is not there then particular sensor sends signal to the controller

- System generates an error and part gets rejected.

- If part is OK them punch mark goes on part and enters in to system database.

- At the end of the shift operator can generate the report.

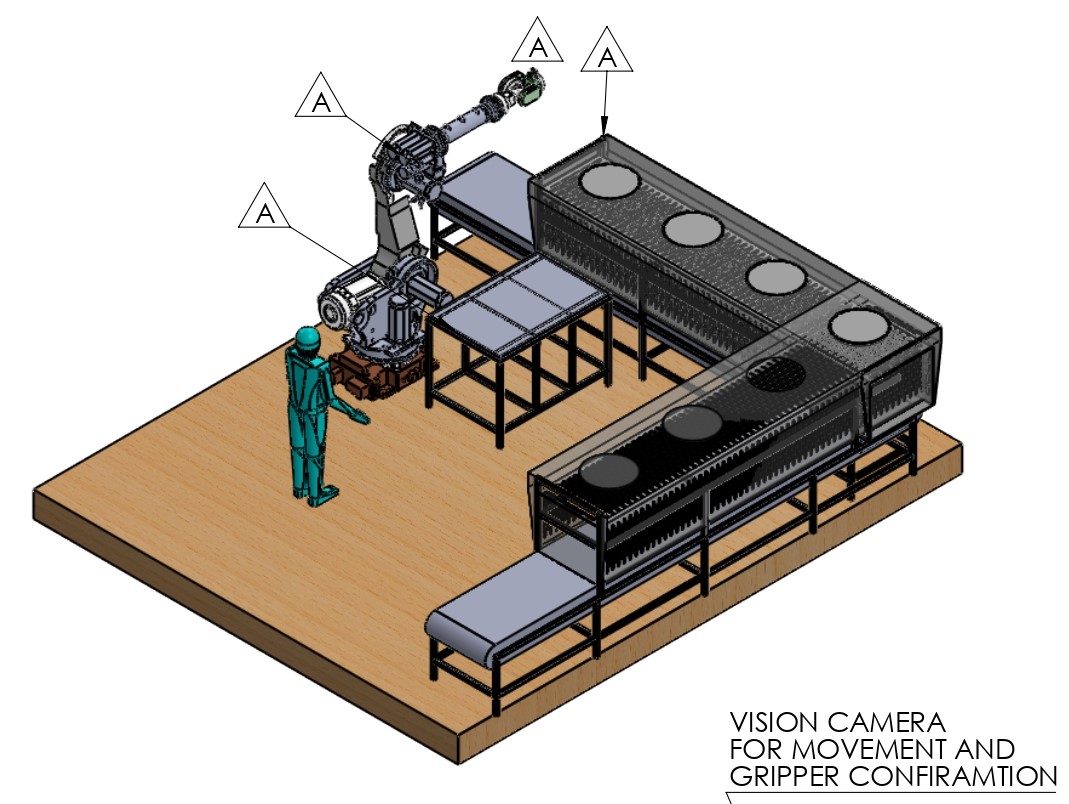

CONVEYOR LINE - COOLING CONVEYOR

Cooling Conveyor line is designed to automatically picked, placed casting part on conveyor line and temperature of that part is reduced from 400 degree to 80 degree Celsius

- Robot picks up part from the another line. part is about 400 degree hot.

- Automated Robot shows part to the QA person for inspection at different set angles.

- When part “OK” from QA person then robot place that part on collong conveyor line for the next process

- If part is not OK then that goes in to “NOT OK” bin.

- OK part travels through the conveyor line. blower and chiller air blow on part for slow cooling.

- Cycle time is achieved by tuning the system.

AUTOMATIC LASER MARKING FIXTURE

This fixture is designed to automatically identify the part variant and laser marking machine prints label accordingly.

- Fixture is designed in such a way that it will identify the part variants automatically as per set program recepie.

- Sensors are mounted in the fixture at various locations (as per design) to identify the part variant.

- These special type of sensors are selected and used as per custom need and requirement of the client for the correct identification of the variant type.

- Variant is identified by sensor as per program feed and sends signal to Laser marking machine.

- Laser marking machine will process the signal and print the particular barcode on part.